✖

Smart 3D-textile-reinforced cementitious materials with microfibers

Abstract

Concrete is the most used construction material in the world, yet its traditional way of use is being challenged by its huge environmental impact and durability issues.

With climate change leading at the top of the political and societal agenda, and with the forecast of growing urban populations, it is necessary to increase the sustainability of the built environment.

This project aims to make concrete structures more sustainable by investigating a new way of reinforcing them. Combining 3D fiber textiles and microfibers, future concrete structures will be slender,

lighter and more durable. While the 3D textiles assure the loadbearing capacity, the short fibers constrain the cracks to a restricted size and assure that the material heals its own cracks.

These smart cementitious materials optimise both the material and the structure, and hence minimize the use of resources, and reduce maintenance and repair costs in order to maximize the service life of future

stuctures. This project wants to investigate how the short fibers, 3D textiles and cementitious matrix fundamentally act together in a synergetic way. The goal of developing a loadbearing and durable cementitious

composite directs the experimental program: all aspects of mechanical performance under monotonic as well as repeated loading, durability properties in aggressive environments, and selfhealing capacity

after cracking will be investigated.

Team involved

Ciska Gielis (PhD), Michael El Kadi (Postdoc), Tine Tysmans (Promotor VUB), Didier Snoeck (Promotor)

✖

Effect of superabsorbent polymers on the moisture transport of alkali-activated slag and its mechanism

Abstract

In this study, superabsorbent polymers (SAPs) and two expansive additives (a MgO-based expansion agent and gypsum) were studied to possibly mitigate the shrinkage of AAS

(alkali-activated slag) systems. To this end, an experimental study was carried out to evaluate the effect of SAPs and the expansive additives on the setting time, compressive strength, autogenous

shrinkage, and total shrinkage of AAS. SAPs prolonged the setting time of AAS and decreased the compressive strength, while the expansive additives shortened the setting time of AAS. When gypsum was

used as an expansive additive, the shortest initial setting time of AAS was less than 10 min. SAPs have a significant effect in reducing the autogenous shrinkage of AAS, and a better result was

achieved when used together with the MgO-based expansion agent as the SAPs promoted the consumption of MgO. The 1H low-field NMR results showed that when the SAPs and gypsum were used together,

the absorption capacity of the SAPs decreased, and part of the absorbed liquid was rapidly released back into the mortar matrix. However, for the total shrinkage, the SAPs were less effective.

SAPs increased the mass loss of the AAS mortar upon drying, which may increase the drying shrinkage of AAS and counteract part of the reduction in autogenous shrinkage.

Team involved

Jingbin Yang (PhD), Didier Snoeck (Promotor), Nele De Belie (Promotor Ghent), Zhenping Sun (Promotor Tongji)

✖

In-situ polymerized superabsorbent polymers for durable cementitious materials

Abstract

When a cementitious material is hardening, it may show shrinkage cracking. The ingress of water containing potentially harmful substances through these cracks could endanger the durability of a

structure. The goal of this project is to enhance the overall durability by limiting the observed shrinkage cracking and to seal the remaining cracks in existing structures by using superabsorbent polymers

(SAPs), materials which are able to absorb huge amounts of liquids. The subject of this project is a new and innovative technique of polymerizing these SAPs in situ, meaning during hardening of the

cementitious material or on a cementitious substrate both in fresh and hardened state. This project aims to investigate proper in-situ polymerizable SAPs, to mitigate plastic shrinkage of fresh concrete

and/or to seal cracks in existing structures by using an external insitu polymerized SAP layer. Additionally, the SAPs will be in-situ polymerized during mixing of all cementitious constituents to induce

internal curing and thus to mitigate autogenous shrinkage. High-tech techniques (e.g. NMR) will be used to monitor the polymerization and to investigate the influence on various cementitious properties. The

research will shed more light on the fundamental interactions between water, SAPs and cementitious materials.

Team involved

Didier Snoeck (Postdoc), Nele De Belie (Promotor Ghent)

✖

Innovative SuperAbsorbent Polymers for crack mitigation and increased service life of concrete structures

Abstract

Superabsorbent polymers (SAPs) are often used in cementitious materials for various purposes, and there was a lack of studies describing the use of SAPs in large-scale concrete

structures under realistic conditions. This paper presents results of an in-field testing campaign where SAPs were used in a large-scale demonstrator. Commercial SAPs and in-house-developed SAPs (constituted

of an alkali-stable and alkali-unstable crosslinker, for a tailored swelling behavior) were used. Five reinforced-concrete walls (14 m × 2.75 m × 0.80 m) were built and monitored with regards to shrinkage-

cracking with demountable strain gauges and optical-fiber sensors. A laboratory campaign was performed simultaneously to characterize the concrete mixtures. The addition of SAPs promoted a reduction of up

to 75% of shrinkage strains in the first 7 days. No cracks have developed in the SAP walls up to 5 months, while the reference wall cracked 5 days after casting.

Team involved

José Roberto Tenório Filho (PhD), Didier Snoeck (Promotor), Nele De Belie (Promotor Ghent)

✖

Monitoring the reduction in shrinkage cracking and improvement in self-sealing and self-healing of concrete through the inclusion of superabsorbent polymers and nano-reinforcement

Abstract

In cementitious mixtures with a low water-to-cement ratio, autogenous shrinkage and cracking due to restrained shrinkage pose a severe problem. To reduce the risk of autogenous shrinkage

cracking, internal curing by means of superabsorbent polymers (SAP) was applied. The drawback is that macropores are created upon the release of water by the polymers. The latter reduces the mechanical properties

of the material. To counteract this strength reduction, nanosilica is introduced to the internal curing mixture. The effect of additives on the restrained shrinkage of mortar was evaluated by means of the

restrained shrinkage ring test accompanied by acoustic emission (AE). AE enabled the monitoring of the hydration process, indicating when the absorbed water was released by the SAPs, while it also pointed out

the moment of fracture of the ring. Results showed that combining SAPs and nanosilica, a mixture was created that decreased shrinkage while maintaining the mechanical properties of the reference material.

Team involved

Gerlinde Lefever (PhD), Nele De Belie (Promotor Ghent), Danny Van Hemelrijck (Promotor VUB), Dimitris Aggelis (Promotor VUB), Didier Snoeck (Promotor)

✖

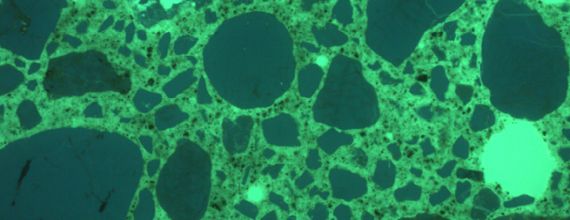

Water interactions down to the nanoscale in cementitious materials with superabsorbent polymers

Abstract

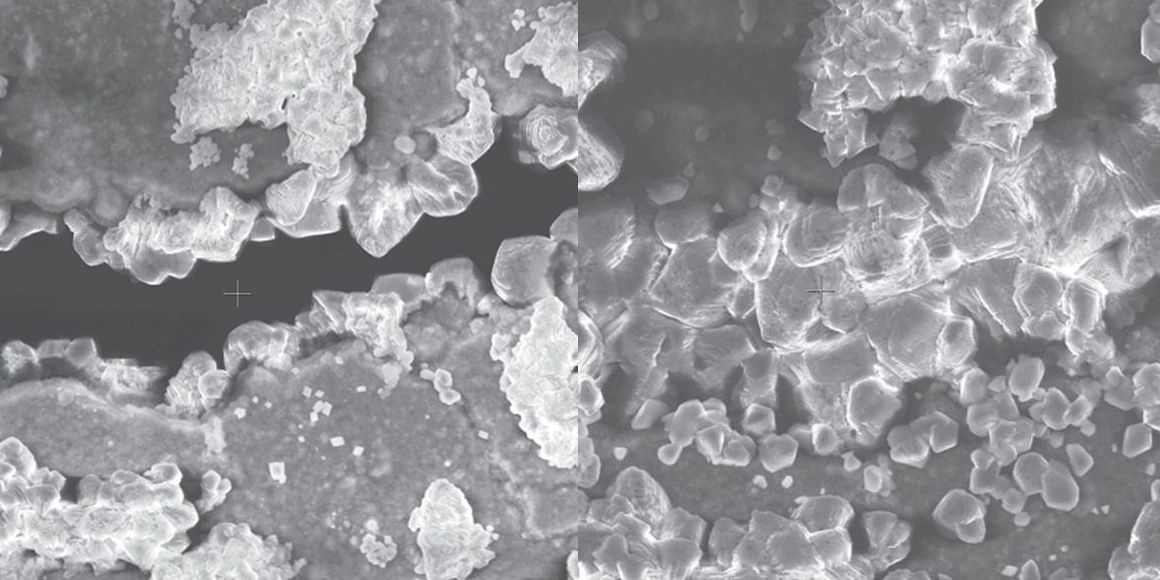

Superabsorbent polymers (SAPs) are able to absorb up to 500 times their weight in water and are used in concrete to mitigate shrinkage and to promote autogenous healing. But, the water

exchange between SAPs and the cementitious matrix still needs to be investigated thoroughly. In that way, a better understanding of the formed microstructure, internal curing and self-healing

will be achieved. As there will always be unhydrated cement particles in the matrix, the water release from the SAPs due to internal curing may lead to a change in microstructure over time,

both at the micro- and the nano-level. The latter can be studied by means of dynamic water vapour sorption (DVS) measurements and nuclear magnetic resonance (NMR). DVS is able to

qualitatively provide information but the quantitative aspect still needs to be investigated and the proposed models need to be validated. Therefore, the additional information from NMR may link

all obtained results in order to quantitatively evaluate the effects of SAPs on the microstructure of cementitious materials. Furthermore, as SAPs promote autogenous (self-)healing due to release of

water towards the cementitious matrix, DVS and NMR can provide additional information on the mechanisms governing this healing capacity and the formed healing products.

Team involved

Didier Snoeck (Postdoc), Nele De Belie (Promotor Ghent)

✖

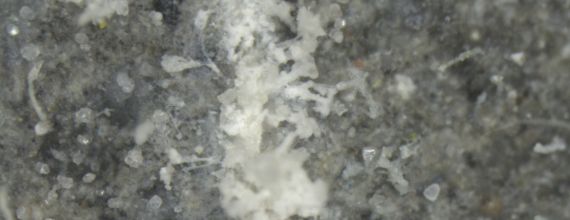

The durability of fractured concrete may be endangered due to the ingress of harmful substances. Without proper immediate repair, the future costs for renovation will rise. How can we solve

this? Concrete has an autogenous healing capacity, but this is not optimally used. There are three criteria to obtain self-healing. First, the building stones for healing need to be present. The second

point is the limitation of the crack width since small cracks are easier to heal. Thirdly, water needs to be present in the matrix to react with the building blocks and glue them together. This is

obtained by mixing in superabsorbent polymers (SAP). These polymers can take up a significant amount of fluid from the environment and provide it to the cementitious matrix for self-healing.

However, they also absorb mixing water and create macropores, causing a decrease in strength. By coating the SAP, this negative effect will be avoided. Also, the microstructure is changed by

mixing in un-coated superabsorbent polymers. Analysis of water vapor sorption isotherms can give useful information concerning the microstructure of porous materials. Still, this

methodology is not often applied on concrete and a lot of questions remain regarding the proper interpretation. During this study, the fundamental interactions between water, superabsorbent

polymers and cementitious materials will be investigated in detail and a smart self-healing material will be designed which will lead to less repair costs.

Team involved

Didier Snoeck (PhD), Peter Dubruel (Promotor Ghent), Nele De Belie (Promotor Ghent)

✖

Sulphur Concrete, to enhance the structural integrity and durability of the material

Abstract

Water is becoming a precious resource on Earth and is almost non-existent on celestial objects. As it is used in the making of concrete, we should start thinking about the use of other sustainable

resources for building new civil applications. Sulphur concrete is a promising thermoplastic material, that does not require either cement or water. However, at present, it is only used in small

quantities due to the temperature limitations and thermal contraction cracking. The aim of this project is to develop a reliable circular sulphur concrete by means of a performance-based

experimental-modelling approach. The parameters are the mechanical and durability properties upon repeated heating, and the link with crystal formation.

Team involved

Qinjian Wang (PhD), Qiong Liu (Postdoc), Didier Snoeck (Promotor)

✖

From Waste to Strength: Assessing the Structural Qualities of Reused Formwork Wood

Abstract

In Belgium, as well as in numerous countries globally, standard-quality wood serves as a building material in a plethora of applications. From permanent structures to temporary solutions, it finds

use in auxiliary constructions such as scaffolding and formwork. Formwork wood is abundantly used during construction and represents up to 30% of the total on-site waste. However, it has a limited

lifespan due to the on-site solicitations. This research studies and explores the reuse possibilities of formwork wood materials in structural applications. The first step is to learn more about the

uses and waste management of formwork wood in Belgium by contacting different wood associations, construction companies, and associations upcycling and reusing construction materials. In parallel,

the formwork wood material is collected on several construction sites and prefabrication centres. Its mechanical properties are determined through bending, traction, compression, and non-destructive

tests. Subsequently, a database is created to catalogue the gathered waste wood along with its properties. A spatial structure is then designed based on the studied properties of the formwork wood.

The goal is to find new structural applications and to design a spatial structure with upcycled formwork wood materials to valorize the at-disposal wood material.

Team involved

Gabrielle Nicolas (PhD), Didier Snoeck (Promotor), Lars De Laet (Co-promotor VUB)

✖

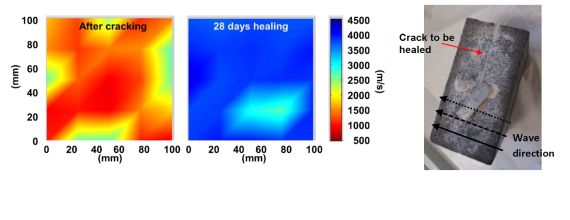

Monitoring of self-healing within cementitious materials including superabsorbent polymers by means of elastic waves

Abstract

The inclusion of superabsorbent polymers to cementitious materials enables the improvement of the self-healing ability through a more continuous water supply. Using surface ultrasonic measurements,

the closure of cracks was monitored over time and could be correlated to microscopic analysis, but no information regarding healing at different depths is available. However, the link with the regain in

mechanical performance, being the ultimate goal of a self-healing material, should still be assessed. The sensitivity of ultrasound waves to the elastic properties of materials suggests a quantification of

the stiffness of formed healing products, which allows the predict the healing capacity in a nondestructive way. Additionally, ultrasonic tomography will provide more information on the location of

effectively healed zones inside the crack by means of scanning the entire surface. Lastly, the establishment of a contactless ultrasound set-up will facilitate the measurements, allow for in-situ

monitoring of the self-healing mechanism and introduce the possibility of automated evaluation.

Team involved

Gerlinde Lefever (PostDoc), Dimitris Aggelis (Promotor VUB), Danny Van Hemelrijck (Co-promotor VUB), Didier Snoeck (Co-promotor)